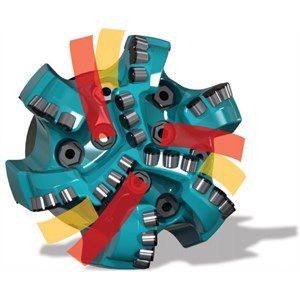

LAGCOE TECHNOLOFY SHOWCASE: ULTERRA SPLITBLADE PDC BIT

Drilling in clay formations offers a number of challenges, with drilling  cuttings management likely topping most directional drillers’ lists. Clay not only clogs tool faces, it creates very long cuttings that will wind up the drillstring, slowing rate-of-penetration and operational performance. Increasing the weight on the bit reaches an inflection, or flounder point, at which increasing the weight on the bit will rapidly decrease rate-of-penetration. When a high rate-of-penetration is achieved, cuttings volume also increases, reducing overall performance.

cuttings management likely topping most directional drillers’ lists. Clay not only clogs tool faces, it creates very long cuttings that will wind up the drillstring, slowing rate-of-penetration and operational performance. Increasing the weight on the bit reaches an inflection, or flounder point, at which increasing the weight on the bit will rapidly decrease rate-of-penetration. When a high rate-of-penetration is achieved, cuttings volume also increases, reducing overall performance.

The Ulterra SplitBlade PDC bit includes three key features to deliver a cleaner tool face for faster drilling. The primary blades are separated after the cone and the outer shoulders are rotated, freeing up more area for the junk slot. Double barreled hydraulics focus on the tool shoulder, ensuring cuttings are swept up the junk slot directly, while a second channel of flow evacuates cuttings from the cone of the bit. This design enables cuttings to be cleared up to seven times faster than possible with conventional PDC bit designs.

Design of the tool face also enables self-piloted directional drilling. Torque changes when drilling a curve with a typical bit. The design of the SplitBlade delivers better cone stability, while the shoulder steers the bit. This configuration tightens the torque band, serving to nearly double rate-of-penetration in directional applications.

In its first year on the market, the SplitBlade has drilled more than 20 MMft, over the course of more than 4,500 runs, averaging 36% more footage than competing bits.

Upload RFQ

Upload RFQ

Twitter

Twitter Linkedin

Linkedin Facebook

Facebook YouTube

YouTube Sales@toplandoil.com

Sales@toplandoil.com +86 21-50890868

+86 21-50890868 Head Office: 8-1011,Lane 5600, Chuansha Road, Pudong, Shanghai, China

Head Office: 8-1011,Lane 5600, Chuansha Road, Pudong, Shanghai, China