- categories

- home

- sourcing center

- top advantages

- top drive parts

- news and media

- download

Model/PN: HHF-1000 FLUID END

Brand: YINDA

Standard: API 8C

Lead Time: 20 days

Warranty: 12 Months

Place of Origin: China

Payment Method: T/T

Application: Oilfields equipments & Spares

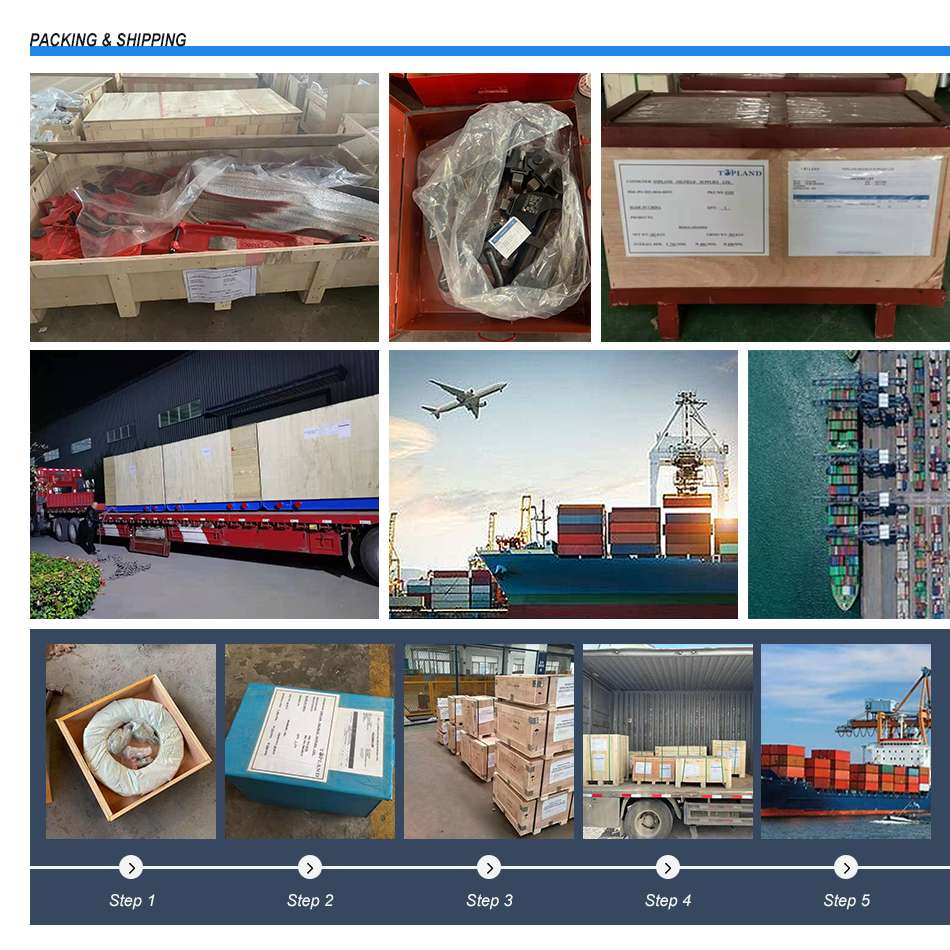

Packaging: Export Standard Pack

HS code: 8431499900

Unit Weight: 500Kgs

Purchase Quantity

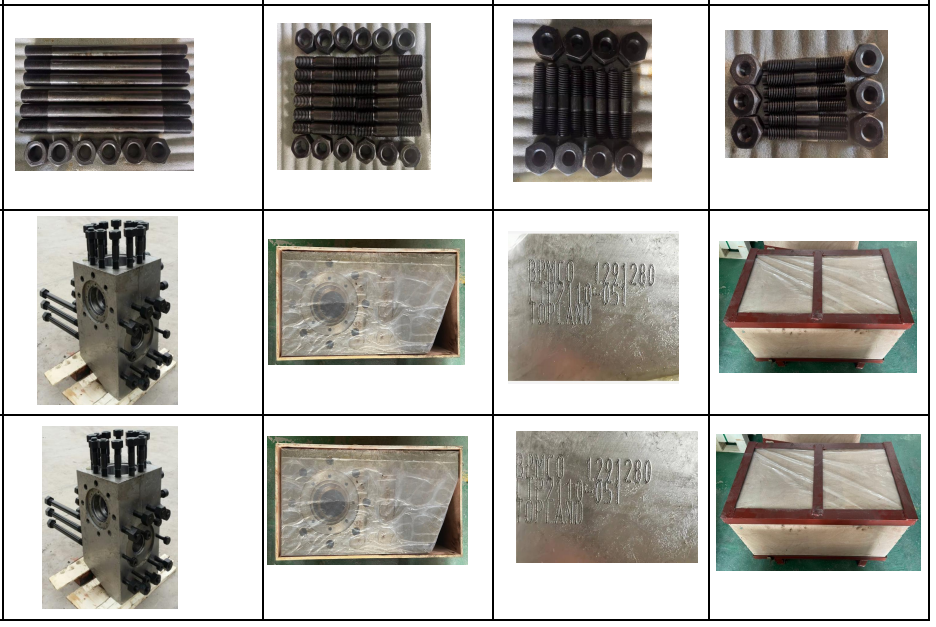

Topland's high-strength, triple reduction, forged steel triplex fluid end modules are made from 4135 alloy steel, heat treated for a long working life, machined to perfection and packaged for delivery with anti-corrosion protection.

Features: Completely interchangeable with OEM Premium forged alloy steel Made on CNC boring mills Strict computer controlled heat treat procedures Rigid inspection Rated for all drilling operations under 5000psi, 7500 psi, and 1000 psi pressure.

Hydraulic cylinder is also called the valve box, it is a major part to the fluid end parts. Blank forged by highstrength alloy steel. After heat treated, with multi-channel processes. The three cylinders of each pump is interchangeable. The following key parts: cone sawtooth thread of cylinder head, connect of the curve of all the screw hole and inner cavity.

Topland can supply modules forged by alloy 35CrMo or 40CrMoMn. It is of high quality with secondary smelting, and with deoxygenates treatment. It is manufactured according to JB/TQ252-81 Specification and with high mechanical performance. Topland supplies a complete line of interchangeable fluid end modules and accessories for triplex mud pumps. Fluid ends and components are interchangeable to OEM’s such as National, Emsco, Gardner Denver, Bomco, Ideco,Weatherford, Drillmec, Texma, Mud King, Honghua, RG, RS, GPM, LS-NOW, Wirth and Oilwell.