WHAT'S NEW IN WELL LOGGING AND FORMATION EVALUATION

Recent advancements in logging-while drilling and wireline logging technology have improved the industry’s ability to place wells in the reservoir, evaluate adjacent formations, and understand targeted reservoirs and the rocks and fluids that comprise them.

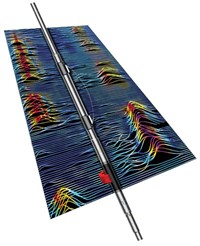

Halliburton reports that its EarthStar resistivity LWD service can detect and map reservoir and fluid boundaries located more than 225 ft (68 m) from the wellbore, at least twice the range of previously available systems. The new service combines deep-reading resistivity measurements, azimuthal sensitivity and advanced inversion processing to determine the orientation of formation layers, and the position and resistivity of fluids in them. The service also provides 3D images, which are used in combination with real-time geosteering software to optimize well placement.

The service’s deep reading resistivity can be used to map pockets of hydrocarbons along the wellbore, identifying potentially bypassed pay. This contributes to improved reservoir evaluation and more efficient field development, Halliburton maintains.

The ultra-deep resistivity measurements also enhance real-time steering decisions. Geosteering engineers are alerted if the well is about to leave the reservoir and are warned about potential hazards ahead of the bit, so they can stop drilling before a sidetrack is needed, eliminating pilot holes. With improved LWD measurements, drillers can be more confident in placing wells above the oil/water contact for optimum completion and production.

Halliburton reports that the EarthStar service has been successfully applied in deepwater and mature field applications. In one North Sea well drilling through a carbonate reservoir that had been partially water-flooded, the deep reading logs identified a bypassed productive zone that subsequently contributed to the field’s output, Halliburton said.

GEOSTEERING IN SHALE

Nabors Industries’ Accusteer measurement and LWD system has been applied successfully for geosteering in shale formations in the Permian and other North American basins. Packaged in a 30-ft collar, the 4¾-in. OD Accusteer system acquires a unique combination of measurements that, in addition to directional readings, include azimuthal gamma, continuous inclination, annulus pressure (ECD), shock and vibration, stick-slip, and downhole weight on bit. The larger 6¾-in. tools also can include propagation resistivity sensors. The system uses a switching telemetry scheme that eliminates toolfaces while rotating to maximize bandwidth and log quality.

The system’s 16-sector azimuthal gamma ray measurement (compared to total gamma ray) provides high-resolution image logs that are used to identify formation layers and guide the bottomhole assembly within them. Continuous inclination near the bit and instantaneous dogleg severity calculations provide continual awareness and enhanced control over the wellbore’s trajectory.

Drilling dynamics measurements—unusual in such a small diameter system—are designed to provide real-time data on mud motor operating performance, help prevent sticking, and improve sliding efficiency.

In a West Texas application, the Auccusteer measurements helped the operator drill an 8,125-ft lateral 100% within the target zone in just two days. Azimuthal gamma readings helped maintain the well in a faster-drilling bed for 4,000 ft without sliding to correct inclination.

In Oklahoma, Nabors reports that the azimuthal gamma measurements helped one operator land the wellbore at the right depth and then keep 100% of the 5,200-ft lateral within the target zone.

HIGH TEMPERATURE LWD

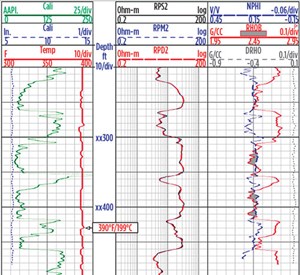

Weatherford International recently introduced the HeatWave Extreme (HEX) HPHT LWD system, specifically for deepwater applications, Fig. 1. Rated at 392°F (200°C) and 30,000 psi for up to 200 operating hours, the system includes gamma ray, resistivity, density and neutron, as well as pressure while drilling sensors. Weatherford developed the technology along with a major operator to operate in hostile conditions.

After a nine-month development project, Weatherford deployed the HEX service in 22 high-temperature offshore wells in the Gulf of Thailand, acquiring real-time and recorded data for a total of 1,650 hours, logging 150,282 ft (45,806 m) of hole, with some bottomhole temperatures exceeding 347°F (175°C).

No temperature-mitigation efforts, such as reducing rpm, controlling the rate of penetration, or circulating to cool the BHA were required. The 22 wells were drilled and logged in an average of 6.2 days per well.

ACOUSTIC IMAGING LWD

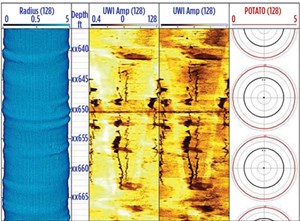

Weatherford also has introduced a high-resolution wellbore imaging LWD system, called the Ultrawave Ultra-Sonic Imager, which can operate in water- and oil-base mud, Fig. 2.

The imager records 360° measurements of the amplitude and travel time of ultrasonic acoustic waves reflected from the borehole wall. The reflected amplitude image reveals bedding, natural fractures, and secondary porosity, induced fractures and borehole breakout. The travel time image produces high-resolution standoff and borehole caliper images to analyze borehole stability. Imaging can be used while drilling to optimize the placement and completion of wellbores in unconventional reservoirs. The system also detects artificial fracture network connectivity to mitigate frac hits in shale wells and to help operators design frac treatments and completions accordingly.

MULTI-FREQUENCY DIELECTRIC

Openhole wireline logging technology continues to become increasingly sophisticated with new measurements being combined with suites of established sensors. The Array Dielectric Xplorer service from Baker Hughes, a GE company (BHGE), is a recent example.

Standard resistivity measurements rely on the conductivity difference between oil and salt water to detect hydrocarbons adjacent to the wellbore. When the formation water is fresh and non-conductive, resistivity logs are not reliable. The new system uses multi-frequency dielectric technology to acquire dielectric permittivity measurements to determine hydrocarbon saturation with any formation water salinity.

A significant advancement over prior dielectric instruments, the Array Dielectric eXplorer uses four 1-in. spaced receivers with three pairs of transmitters placed symmetrically above and below. The electromagnetic propagation transmitters operate at five frequencies from tens of megahertz to one gigahertz, and at multiple depths of investigation. Based on transmitter–receiver combinations, the system has six spacings. Data is acquired at each of these spacings, and for each of the five frequencies, to provide borehole-corrected apparent formation resistivity and permittivity values. Petrophysical deliverables include flushed zone resistivity, water-filled porosity, water salinity, and rock textural parameters.

The system allows for fast logging speeds and is combinable with other BHGE wireline services, like the FLeX mineralogical service and the MReX magnetic resonance service, to provide a full understanding of reservoir minerals and total porosity.

The result of a 2.5-year development project, the Array Dielectric Xplorer service has been successfully introduced in several regions including the Middle East, Africa, and the United States.

MAGNETIC RESONANCE SERVICE

Halliburton advanced wireline nuclear magnetic resonance (NMR) logging technology by introducing its new Xaminer Magnetic Resonance Service (XMR), Fig. 3. Recall that instead of evaluating reservoir rock, NMR detects the fluids in the pore spaces to provide measurements of fluid volume, porosity, and permeability.

Halliburton reports that the Xaminer service provides improved vertical resolution of thin beds and helps evaluate organic shales, carbonates, turbidites, and tight gas reservoirs. It also can detect and quantify gas, condensate, water and heavy-to-light oils in the formation.

The new service acquires eight times more data with less than half the power of traditional NMR sensors. It provides 2D and 3D images and enables analysis by distinguishing moveable fluids from capillary bound and micro-porosity held fluids.

The XMR service acquires data in a single pass and can be combined with other logging sensors for comprehensive formation evaluation. The service also can help operators identify unrecoverable reserves before investing in attempts to develop them. Halliburton reports that XMR logs helped a West Texas operator evaluate a carbonate reservoir, finding unrecoverable oil and salt water zones, saving the cost of production testing.

PRESSURE TESTING AND FLUID SAMPLING

BHGE continues to develop enhanced methods for wireline formation pressure testing and fluid sampling. The company’s new FTeX advanced wireline formation pressure testing service delivers pressure data by combining downhole automation with precise drawdown control, Fig. 4. BHGE claims the new service can obtain pressure profiles, fluid contact, and mobility information as early as the first logging run, because the service can be combined with other formation evaluation measurements.

Traditional wireline pressure testing services require significant manual control. Field engineers need to analyze initial formation responses and adjust test parameters to achieve stable conditions needed for accurate readings. This conventional process is prone to longer testing times and increases the risk of inaccurate or incomplete tests, especially in low mobility environments.

The new service includes artificial intelligence in the downhole system combined with precise control over the downhole pump, eliminating the need for manual control from surface. The system analyzes the pressure response 100 times per second and automatically adjusts the test parameters to optimize the test time and improve measurement accuracy. Results enable petrophysicists to make earlier decisions on meeting their evaluation objectives, BHGE asserts.

The service is fully combinable with BHGE’s other wireline logging services, and has a smaller area of contact with the hole wall than other methods, reducing the risk of sticking.

The FTeX service has been deployed globally from offshore fields in the Asia Pacific region, the North Sea and the Gulf of Mexico to onshore fields in the Middle East and Latin America. Offshore Vietnam, the system performed 29 pressure tests in a well through a depleted, low mobility reservoir. With a drawdown rate of .004 cc/sec, a stable pressure measurement was achieved within 15 min. In a North Sea well with variable formation permeability, the system took readings at 50 pressure stations in 20 hrs, half the time required by previous methods. Also, BHGE reports that the system performed pressure tests at 200 stations in a Gulf of Mexico well in an average of six minutes per station in reservoirs with 0.1 to 1 mD/cp mobility.

BHGE also has made several incremental improvements to its established Reservoir Characterization eXplorer (RCX) wireline service platform for measuring formation pressure and obtaining multiple clean fluid samples. The RCX service includes a surface-controllable packer section for variable volume and variable-rate drawdown, downhole evaluation of fluid to assure clean samples, and small and large displacement pumps. A multi-tank carrier system enables recovery of up to 52 samples in a single run.

The improved RCX service enables fluid sampling in high pressure, high temperature wells, up to 27,000 psi and 375°F (191°C).

The new RCX eXceL (Fig. 5.) extends the RCX platform sampling capabilities into low permeability formations without the need of inflatable packers. In very low permeability formations (~1 mD/cp) with large flowing pressure differential, large flow areas are needed to achieve efficient sampling operations. Until now, large sampling flowing areas could only be achieved by using inflatable single- or straddle packers, which complicate sampling and risk sticking, especially in slim holes.

The RCX eXceL is a probe-based sampling service with a 33-in2probe area open to flow, resulting in a high flowrate with minimal pressure drop. The larger flow area also reduces the speed of the fluid at the sand face, reducing the seal losses caused by erosion in unconsolidated formations.

BHGE reports that the RCX service has been used in hostile well conditions in Southeast Asia, where it collected 22 samples from seven depths in two wells, and in the North Sea where operators have used it to gather samples from extremely tight formations and in slimhole HPHT applications.

CASED HOLE PULSED NEUTRON

Cased hole logging can be an effective means of evaluating formations behind pipe and finding bypassed oil and gas zones. Schlumberger recently introduced a new pulsed neutron service for cased hole formation evaluation logging. The Pulsar multifunction spectroscopy service combines multiple detectors with a high-output pulsed neutron source for cased hole formation evaluation and reservoir monitoring. Results, which are equivalent to openhole logging methods, can be used to optimize completion design and maximize production. Unlike conventional cased hole logging, the Pulsar service does not rely on openhole data input to obtain a high-resolution volumetric petrographic interpretation, so rigless well logging can be conducted without disrupting drilling operations. Logging a well after it has been cased also eliminates well instability risks common in laterals and shale reservoirs.

The service’s high neutron output and improved acquisition accuracy increase logging speed and measurement precision, Schlumberger says. The system acquires a suite of self-compensated traditional cased hole measurements, including sigma, porosity, and carbon/oxygen ratio. The service also detects an expanded set of elements including total organic carbon (TOC). In addition, a new fast neutron cross section (FNXS) measurement differentiates and quantifies gas-filled porosity from liquid-filled and tight zones.

Schlumberger reports that because the Pulsar service does not depend on conventional resistivity-based approaches to rock and fluid identification, it can accurately determine saturations in any formation water salinity. It can determine mineralogy, lithology, and fluid content profiles in horizontal, deviated, and vertical wells. The service also can identify hydrocarbons in low-resistivity pay.

The downhole tool is packaged for hostile well conditions with a corrosion-resistant housing. The 1.72-in. diameter tool can operate at up to 347°F (175°C) without a flask. Applications for the new service include formation evaluation for diagnosis of bypassed hydrocarbons, depleted reservoirs, and gas zones; logging in old wells where modern openhole logs have not been run; and element logs for well-to-well correlation and sequence stratigraphy.

In a U.S. land well, Pulsar logging in shaley sand revealed two zones of interest at X,160 to X,180 ft and X,270 to X,330 ft, Fig. 6. The environmentally corrected FNXS curve and the gas ratio curve it is calculated from (Tracks 7 and 6, respectively) show that the lower zone contains gas—unlike the very low porosity upper zone. The stand-alone volumetric interpretation performed using a linear solver with Pulsar service’s sigma, FNXS, and TPHI measurements (Tracks 10 and 11) was validated by the previously obtained openhole logs (Tracks 8 and 9).

According to Schlumberger, with this one-run, one-tool solution to logging cased wells, the operator can streamline operations to a single log obtained in the more stable cased well.

Weatherford’s Raptor 2.0 cased-hole evaluation tool is a pulsed-neutron logging system that uses enhanced sigma and carbon/oxygen techniques to measure oil-water saturation and a proprietary N-vision technique to quantify gas-liquid saturation through casing, Fig. 7. The system includes a pulsed neutron generator; four spectroscopic lanthanum-bromide (LaBr3) detectors, compared to two detectors in previous tools; a fast-neutron counter for precise measurement of the neutron emission rate; and a telemetry cartridge that enables the service to be combined with production logging and cement evaluation tools. The company also provides software and petrophysical services to help operators identify hydrocarbon location, type and volume.

Since its introduction in 2017, Weatherford notes that the Raptor 2.0 system has been used in Canada to identify productive reservoirs that were undetected by historical openhole logs. In Malaysia, the system was used in five wells with large dual-string casing to identify a shallow, oil bearing sand. In India, the system gathered saturation data from more than 80 wells to monitor the sweep efficiency of a large water flood project. Weatherford also reports that an operator in continental Europe increased production by a factor of four after pulsed neutron logs revealed new prospective reservoir targets in an existing gas project.

HIGH TECHNOLOGY CORE ANALYSIS

Using the latest digital technology, oil company geologists and petrophysicists can gain more information than ever from physical core samples from the reservoir. In 2017, Halliburton added Ingrain core analysis services to its suite of product lines.

Ingrain’s service captures high resolution, continuous images along the core’s length to gain a better understanding of the pore system and to quantify the relative producibility of the rock.

THROUGH-THE-BIT IMAGING

Schlumberger’s ThruBit through-the-bit logging services acquire image logs in slimhole unconventional wells that provide a better understanding of the reservoir for planning completion and fracturing to optimize production. The new services include the FMI formation microimager log and the Dipole acoustic service. These services use ultra slim 2⅛-in. tools conveyed through the drill pipe to deliver key measurements while eliminating the risk of lost or stuck logging tools.

The ThruBit FMI microimager produces images in water-based muds to provide geological information including fault and fracture detection, dip data and borehole profile.

The ThruBit Dipole service obtains both monopole and cross-dipole waveforms along with Stoneley wave acquisition to deliver a detailed representation of the formations surrounding the borehole. The ThruBit Dipole service can log in either surface readout or memory mode in both open and cased holes.

Compressional, fast and slow shear, and Stoneley slowness measurements are processed with a 3D anisotropy algorithm with respect to the borehole axes to deliver referenced anisotropic moduli. Anisotropy detection enables identification of formation heterogeneity to support the engineered design of hydraulic fracturing operations and to guide selective perforating and sand control. Well placement and stability can be evaluated by combining ThruBit Dipole services’ identification of the stress regime with pore pressure data.

By using both services, combined with other petrophysical outputs—such as density and porosity, engineers can optimize completion placement design for horizontal wells. For example, in the Bakken’s Three Forks formation, the ThruBit FMI microimager and the ThruBit Dipole service demonstrated heterogeneity along the laterals, resulting in completion design optimization and easy prediction of stimulation behavior.

Upload RFQ

Upload RFQ

Twitter

Twitter Linkedin

Linkedin Facebook

Facebook YouTube

YouTube Sales@toplandoil.com

Sales@toplandoil.com +86 21-50890868

+86 21-50890868 Head Office: 8-1011,Lane 5600, Chuansha Road, Pudong, Shanghai, China

Head Office: 8-1011,Lane 5600, Chuansha Road, Pudong, Shanghai, China