BRINGING REAL-TIME DATA AND ANALYSIS FOR INCREASED WELL INTEGRITY AND PERFORMANCE

Offshore and subsea well operators have traditionally faced a great challenge when it comes to monitoring the integrity and performance of their facilities. A pressure increase or a leakage can easily go undetected and ultimately lead to severe issues. This could mean having to cease operations to prevent a blow-out, or even, risk a complete failure and potential loss of the well. In this latter case, it leads to millions of dollars loss, as well as to environmental damage. Having access to real-time data to fully monitor the well’s functioning would help operators avoid such major issues before they occur.

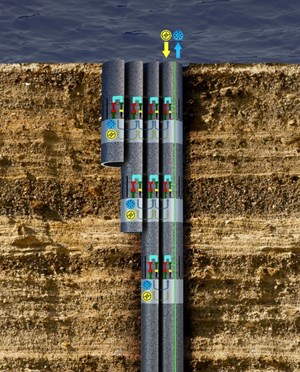

To get it, they can turn to the new Vallourec well monitoring solution. Vallourec has developed a new generation of smart pipes capable to deliver continuous, real-time well data to monitor wells’ integrity and performance. This “Intelligent Pipe solution” uses the slimmest possible sensors. These sensors, which are embedded in the pipes themselves, capture and relay a steady stream of data related to temperature and pressure.

Innovative design concept offers real-time data retrieval

In developing its Intelligent Pipe solution, Vallourec teamed up with OpenField Technology, a specialist in high-tech sensors. Vallourec embeds OpenField’s micro-sensors to the outside of its pipes, ensuring that they function correctly while maintaining the pipes’ structural integrity.

The resulting data capture and retrieval system works on any size pipe, and it has no positioning restrictions related to well depth or annulus. During the well’s installation phase, the system is powered by its own battery. Once installed, continuous power is generated by the Intelligent Pipe system installed on the tubing, which is connected to the surface via an electrical downhole cable. This cable ensures the power supply of the tubing system as well as the data retrieval for all Intelligent Pipe systems deployed in the well. Non-magnetic pipes connect the Intelligent Pipe casing system to its tubing system, enabling transmission of both power and data. Using a tubular encapsulated cable (TEC), sensor monitoring can literally take place every second, with no limit on how many times monitoring is carried out.

The Intelligent Pipe solution is fit-for-purpose, with a minimum length requirement of just four meters. The sensors themselves provide excellent accuracy and resolution, all while consuming very little energy to ensure permanent well monitoring. They have been optimized in terms of shock and vibration resistance, which is a necessity for the drilling phase.

Reinforcing well integrity

The Intelligent Pipe solution first ensures well integrity. It does this by monitoring pressure and temperature of the entire wellbore in real-time, anticipating any abnormal annulus behavior. Moreover, thanks to real-time monitoring during the production start-up phase, the solution will mitigate the risk of Annular Pressure Buildup (APB). With the ability to maintain the right APB level throughout, production can be optimized without any risk to the well’s integrity.

Operators benefit from a much quicker reaction time as soon as any abnormal well behavior is detected. With the Intelligent Pipe solution, operators are immediately alerted about any leakage. As soon as the anomaly or safety issue is detected, operations can be halted before the problem escalates. This detection speed naturally reinforces well integrity. As action is taken to remedy the safety issue, it becomes much easier to anticipate even greater potential failures that may be coming down the pipe.

Vallourec offers the additional capability of combining its Intelligent Pipe solution with both its Vallourec’s pipe performance database and its Smartengo Running Expert digital solution. In this way, Vallourec can offer a truly complete digital well performance analysis support that optimizes drilling and running operations. Indeed, when combining real well pressure and temperature data provided by the sensors with actual pipe resistance and performance provided by Vallourec pipe database, operators can analyze whether a particular pipe configuration is sustainable for the well operations and loads encountered during the well lifecycle.

Characterizing well environments

The system also offers operators permanent real-time access to key data regarding the environment surrounding the well. This means gaining vital knowledge about the formation beyond the casing, including any geological shifts.

Typically, during the drilling phase, operators have access to equipment and sensors that provide information on the formation and reservoir. However, information on how the formation will act after the drilling phase is complete is impossible to predict. This may include such behaviors as moving formations, impact of injection processes, or impact of a depleted reservoir on geological layers.

This is where Vallourec’s Intelligent Pipe comes in. Its sensors offer a window into what is happening beyond the casing. With the Intelligent Pipe solution, operators gain direct data access on the reservoir itself, including information on how each different production zone is functioning. Having sensors in each zone makes it possible to calculate pressure in each area.

This is a significant capability, as during well production the well might have to be cut off periodically so that logging tools could be run inside to record pressure and calculate flow. The Intelligent Pipe solution renders that need obsolete, as the data monitoring process is permanent. It offers a monitoring platform within the reservoir to implement different sensing elements, including a hydrocarbon / water interface, water saturation, and more. Operators thus have access to reservoir data at any time.

Optimizing Well Performance

Well operators are always trying to optimize the performance of their assets by developing key well parameters during the entire lifecycle, striving for the most efficient levels of production while improving resource management. Traditionally, they have used simulated models to monitor well performance. They create theoretical well loads by inputting load information into a software application, building in safety factors to prevent any overloads.

With the Intelligent Pipe solution, operators learn about their actual well loads for a truly optimized well design, rather than relying on theoretical ones. The Intelligent Pipe’s proprietary sensors gather the well load data in real time, check against simulations, and enable well designs to be adapted and optimized. With concrete data and an optimal design, they can select the proper pipes for their needs.

Vallourec’s Intelligent Pipe currently uses two main parameters to better understand wells: temperature and pressure. The temperature sensors detect channeling in cement, enable theoretical models such as the geological thermal gradient to be adapted to actual data, and even confirm fluid insulation efficiency. Pressure is monitored in real time to optimize the APB level and production rate, and to provide alerts to any abnormal behaviors that may require operations to cease. Leakages are easily detected, so that swift action may be taken to prevent well failure. The Intelligent Pipe solution can even monitor the impact of the well on the surrounding geological layer.

Together, the pressure and temperature data can indicate any issues encountered in the well, such as inside or outside leakage. Vallourec is now adding sensors to the solution that can provide data related to reservoir key parameters and fluid properties within tubing.

A simple, modular, fit-for-purpose solution

The Intelligent Pipe solution is designed to serve the entire well lifecycle, from installation through to decommissioning. For example, it offers data to operators for the plug and abandonment preparation plan by giving information on well annulus integrity and permanent barrier quality for 20 years. There is also the future possibility where the solution could be implemented in a global monitoring approach using a platform designed for post-decommissioning monitoring.

The system also can be used in storage applications such as carbon capture, utilization and storage (CCUS)—it can provide information during the injection phase whereby specific sensors measure CO2 properties within the tube. A specific CO2 detector could furthermore be designed for the post-injection phase, though this is not part of the solution’s current capabilities.

Much more than just an accessory, it is part of a broader Vallourec solution that is being combined with other proprietary systems as SmartengoTM Running Expert or our Vallourec’s pipe database. Using the data gathered, our experts can make simulations, and compare well loads and pipe resistance to assess the pipe integrity during the different well operations of our customers. We can provide a complete support to our customer from the installation of our solution, via our VAM® Field Service network, until the analysis of monitored data via our well design expert.

Intelligent Pipe is qualified as a VAM® connection and has been qualified by a series of R&D tests. Vallourec’s Intelligent Pipe solution will enter the market with the first system set for implementation in early 2021. A major Vallourec customer will be the first to utilize this technology in a complex well installation. With this solution in place, production teams onboard will be able to use the real-time well data to operate more safely and efficiently.

Upload RFQ

Upload RFQ

Twitter

Twitter Linkedin

Linkedin Facebook

Facebook YouTube

YouTube Sales@toplandoil.com

Sales@toplandoil.com +86 21-50890868

+86 21-50890868 Head Office: 8-1011,Lane 5600, Chuansha Road, Pudong, Shanghai, China

Head Office: 8-1011,Lane 5600, Chuansha Road, Pudong, Shanghai, China